UH 60 Parts: How to Ensure Quality and Compatibility

UH 60 Parts: How to Ensure Quality and Compatibility

Blog Article

The Significance of Correctly Sourcing UH-60 Components for Safe and Effective Workflow

The value of properly sourcing UH-60 components can not be overstated, as the integrity and safety of aeronautics operations pivot on the quality of these elements. Making use of licensed parts not just makes certain conformity with extensive design requirements but likewise mitigates the risks related to subpar choices. The ramifications of sourcing choices prolong beyond immediate operational efficiency, impacting long-lasting upkeep expenses and aircraft reliability. As we check out the vital aspects of sourcing carefully, the tactical advantages and surprise challenges might expose insights that are crucial for sustaining functional excellence.

Recognizing UH-60 Component Specs

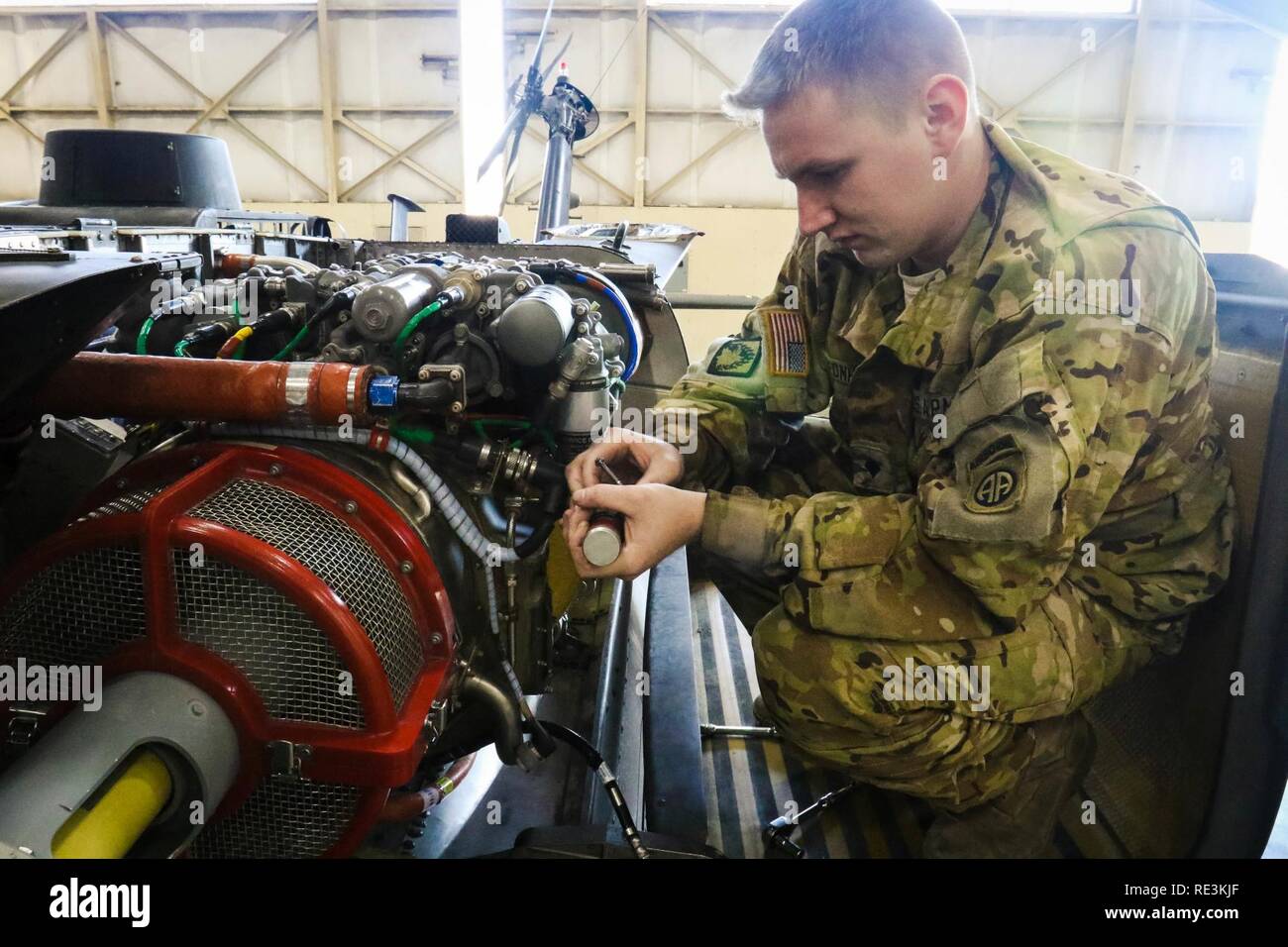

Comprehending the details of UH-60 component specifications is crucial for ensuring operational performance and safety and security in aviation maintenance. The UH-60, widely used in military and private applications, calls for components that fulfill rigorous engineering and regulative requirements. Each component is diligently developed to perform under certain conditions, and inconsistencies in requirements can cause efficiency failures or safety and security threats.

Element requirements include numerous characteristics, consisting of material structure, dimensional tolerances, and functional limits. As an example, rotor blades have to comply with precise weight and aerodynamic profiles to ensure optimal trip qualities. In addition, parts have to undergo strenuous testing to verify their integrity and toughness within the requiring settings normal of aviation procedures.

Additionally, understanding the certification processes related to UH-60 parts is crucial. Each component may birth markings suggesting compliance with armed forces or sector criteria, ensuring that it has actually undergone the necessary inspections and quality analyses. This compliance not just safeguards the aircraft's efficiency however also cultivates accountability amongst makers and vendors. As a result, extensive expertise of part specs is vital for upkeep employees, allowing them to identify authentic components and preserve the functional stability of the UH-60 fleet.

Threats of Using Substandard Components

The honesty of aeronautics procedures depends upon the top quality of parts made use of in aircraft upkeep, specifically for the UH-60. Using substandard components poses significant threats that can compromise both safety and operational effectiveness. These components might not meet the extensive requirements established for armed forces aeronautics, resulting in unforeseeable performance and prospective system failures.

Substandard components can result in increased deterioration on important systems, ultimately shortening the life-span of the airplane and requiring expensive repairs or replacements. Additionally, the usage of inferior materials might bring about disastrous failings during flight, threatening the lives of crew participants and travelers alike.

Furthermore, reliance on non-compliant components can expose operators to legal and regulative effects, as aircraft must adhere to rigid guidelines set forth by regulating bodies. This might lead to grounding of the aircraft and substantial functional hold-ups.

Advantages of Qualified Parts

Qualified parts supply a wide range of benefits that significantly improve the safety and security and integrity of UH-60 operations - uh 60 parts. One of the main advantages of these components is their adherence to rigid top quality requirements. Qualification processes browse around this web-site guarantee that each part has gone through rigorous testing and evaluation, thus validating its efficiency and resilience under numerous operational problems

Service technicians can be confident in the integrity of these parts, reducing the probability of unexpected repair services and enhancing total operational performance. Eventually, investing in qualified parts is vital for the safe and efficient operation of UH-60 airplane.

Sourcing From Trusted Distributors

When sourcing parts for UH-60 airplane, partnering with reliable suppliers is essential to guaranteeing quality and reliability. The safety and performance of army airplane depend dramatically on the honesty of their elements, making it crucial to select providers with a proven performance history in the sector. Respectable vendors stick to rigorous quality control procedures and often hold pertinent accreditations, which work as a testament to their commitment to quality.

Along with quality guarantee, established distributors supply comprehensive support solutions, including technical help, service warranty programs, and prompt delivery. This level of interaction is crucial for preserving functional readiness and reducing downtime. Reliable suppliers are generally much more transparent concerning their sourcing practices, making certain that the parts supplied satisfy rigorous governing standards and are compatible with existing systems.

It is additionally helpful to take into consideration providers that concentrate on UH-60 components, as they possess extensive expertise of the airplane's requirements and demands. By leveraging the proficiency of these distributors, drivers can boost the safety and security and performance of their operations, eventually causing enhanced goal success. Consequently, investing time in sourcing from respectable suppliers is a critical action towards attaining optimum performance in UH-60 aircraft operations.

Long-Term Cost Performance

Attaining long-lasting expense performance in sourcing UH-60 parts needs a critical strategy that balances initial her comment is here investment with continuous operational expenditures. Organizations must prioritize top quality over price, as substandard components might bring about frequent repair work and enhanced downtime, ultimately inflating overall prices. By purchasing dependable, qualified parts, drivers can boost the aircraft's efficiency and longevity, alleviating the danger of unexpected failings.

Furthermore, establishing long-term partnerships with respectable providers can produce economic advantages, such as bulk investing in discounts and positive repayment terms. These partnerships promote access to remarkable products and technical assistance, ensuring that the sourcing procedure straightens with operational demands and regulative standards.

Additionally, carrying out a methodical stock management technique permits far better projecting of component requirements, minimizing excess stock and linked holding prices. Frequently assessing provider performance and part integrity can additionally inform future buying choices, enabling companies to adjust to evolving functional demands successfully.

Ultimately, a focus on lasting cost effectiveness in sourcing UH-60 components not just safeguards operational integrity but likewise adds to an extra sustainable economic model, allowing for reinvestment in essential aeronautics capabilities.

Conclusion

In conclusion, the appropriate sourcing of UH-60 parts is essential for maintaining safe and efficient aviation procedures. Following stringent specs and utilizing licensed parts mitigates the dangers associated with second-rate components. Engaging with reliable suppliers not just makes sure compliance with regulative standards but additionally enhances overall reliability and efficiency. Ultimately, prioritizing high quality over price adds to lasting price efficiency, decreasing unintended upkeep and downtime while protecting the operational integrity and durability of the aircraft.

The value of correctly sourcing UH-60 components can not be overstated, as the stability and safety of air travel operations hinge on the top quality of these elements.Recognizing the intricacies of UH-60 part specifications is essential for guaranteeing functional efficiency and security in aviation maintenance. Detailed understanding of part requirements is crucial for upkeep personnel, allowing them to recognize authentic elements and preserve the operational integrity of the UH-60 fleet.

When sourcing parts for UH-60 aircraft, partnering with respectable distributors is important to making sure high quality and dependability.Attaining long-lasting price efficiency in sourcing UH-60 parts calls for a critical strategy that balances initial investment additional reading with recurring functional expenditures.

Report this page